Constant Force Spring

Constant Force Spring is a mechanical instrument typically used to store energy and then release it, absorb the shock that occurs, or provide a force between the surfaces in contact. They are made of flexible materials formed in the form of a helix that returns to its initial length when left.

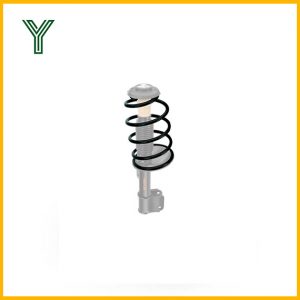

Under tension or compression, a Constant Force Spring. The spring characteristics therefore depend on the cutting module. The Constant Force Spring for vehicles is generally made of hardened steel. An instrument called an automatic wrapper allows it to be easily shaped by taking the heated Spring Wire. The machine picks up the wire and directs it to the spinning rod and pushes it along the rod to create multiple coils.

Bow Rate

Spring ratio is a measure of how much force must be applied until a zemberek spring is compressed by 2.2 centimeters. The bow rate is determined by its maker.

What Are The Types?

Stretching/extension Constant Force Spring designed to withstand stress. It usually has a hook or eye form at both ends for connection.

Compression zemberek springs designed to resist compression. One of the most common uses for compression coil springs is the suspension system of cars.

It is used as a convoluted heavy load compression spring. A strip of plates is rounded as both a helix and a spiral. When compressed, the Strip has stiffer edges than a wire coil. But the spiral arrangement allows the turns to ride on top of each other.

Torsion zemberek spring, designed to withstand torsion movements, is another type of spring. It is often associated with garment pegs or up-and-down garage doors.

Places Of Use

Zemberek has many uses. Important ones are the buckling Springs on computer keyboards, car suspensions, bed coils on the inner spring beds, and upholstery Springs

Türkçe

Türkçe العربية

العربية

Reviews

There are no reviews yet.