Force Springs- Quality

Force spring used for the purposes of storing energy through compression or pressure. Providing force, load, or countering forces against pressures is called a force spring. The pressure spring can safely meet this effect by flexing in the direction of the effect of the load or force produced. From metal or metal alloys and acting on it.

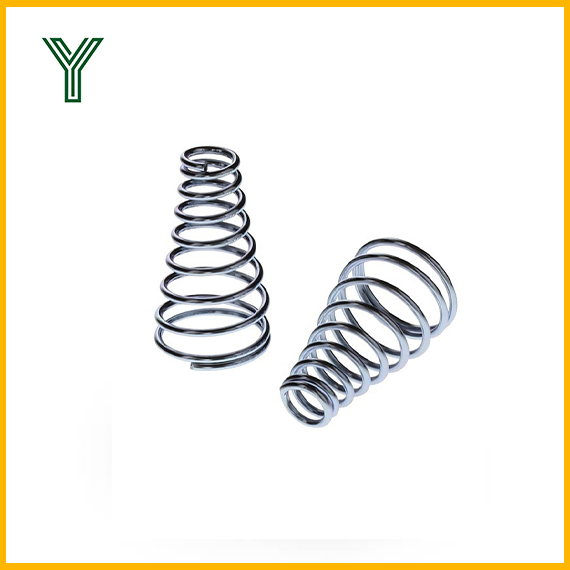

Usually a circular cross-section wire, screw teeth in the form of a helix and brought in a cylindrical shape by winding Springs. cylindrical helical pressure spring is called. In print arcs, the forces are acquired in a linear manner. To obtain a nonlinear force, conical or cask springs are manufactured.

Force Spring Features

In print publication, the ratio of the average spring diameter to the diameter of the wire is called the spring Index or winding ratio. This ratio is preferred to be between 4 and 1 and 1 coefficients. In cases where the publication is required to stand upright on the sitting surface, grinding is applied to the end parts of the publication to ensure that it has a smooth sitting surface.

It is possible to produce a print spring using a rectangular or square cross-section wire in the desired situations. Fixed-line, variable-line, grinding cylindrical, non-grinding cylindrical and conical varieties are available. They are also known by different names such as printing Springs, vibration Springs, push Springs, vibration Springs, sieve Springs, Helix Springs, push Springs.

Print springs are produced in four varieties according to the shapes of the end parts. These varieties are open finish, open finish stoned, closed finish, closed finish stoned. The spring is the element that returns to its original state . When the charge or force is eliminated by the effect of the energy it has stored.

Please Contact with us if you need help or any question, LİNK

Türkçe

Türkçe العربية

العربية

Reviews

There are no reviews yet.