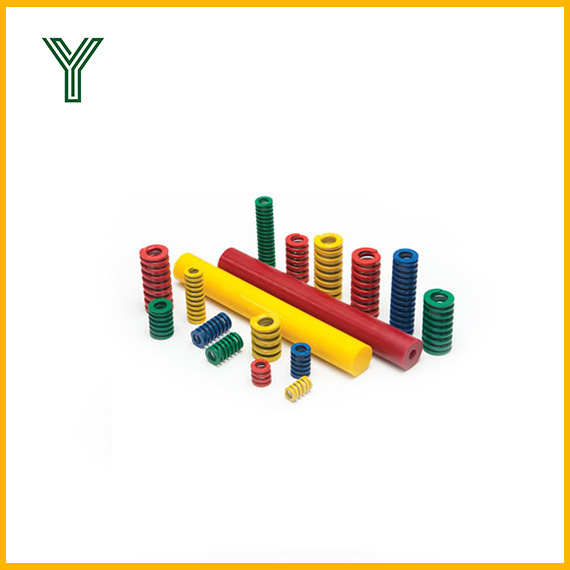

Mold Springs

Mold spring is a solid helical compression spring consisting of rectangular wire commonly used in die sets. For the same value deviations, die Springs carry thirty percent more load. The die spring is designed to carry very high compression loads in hostile environments. Die Springs and derivatives made mainly for staple presses to provide consistent and reliable resistance can also be used in other industries.

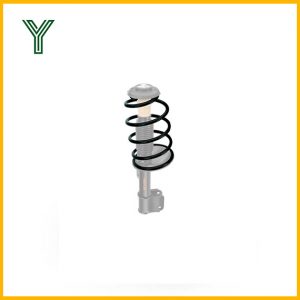

How Do Such Springs Work?

The die spring works similarly to standard compression springs, where energy is stored when a load is applied, and the spring tries to keep the two components separate. A tighter spring wrap provides a higher spring ratio for springs produced from the same wire.

Ingredients

Steel spring wire tempered in oil is a common material for mold spring. Chromium alloys are also among the common materials used for mold spring due to the chrome layer, which adds wear and corrosion resistance. Chromium silicon or chromium vanadium, which increases size accuracy, minimizes individual stress points, and can operate at higher temperatures, are less common. These metals allow the pedestrian application of a flexible colored layer indicating the working load of a publication.

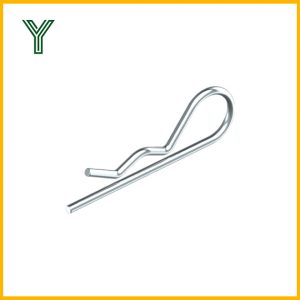

Bow tips and general features

It has two basic configurations: closed and open end for coil ends.

Closed-end die spring: Closed-End mold spring are reduced to the point where the wire end of the coil range remains on the adjacent coil. This makes the broadcast final winding incomplete and ineffective. It might change the broadcast jamming a bit.

Open end die spring: there is no step reduction at the wire termination point in open end die Springs. This creates a rough surface unless it is grounded. However, this may be insignificant in mold machines. Mold spring

Please contact us when you need..

Any question try out live chat

Türkçe

Türkçe العربية

العربية

Reviews

There are no reviews yet.